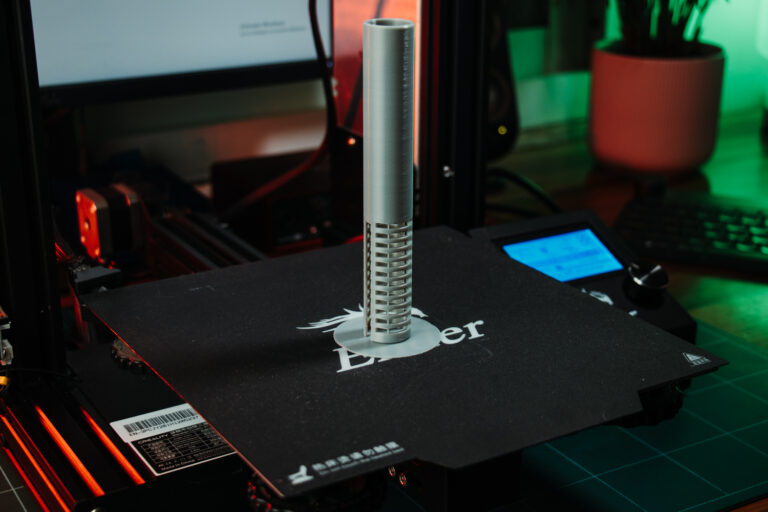

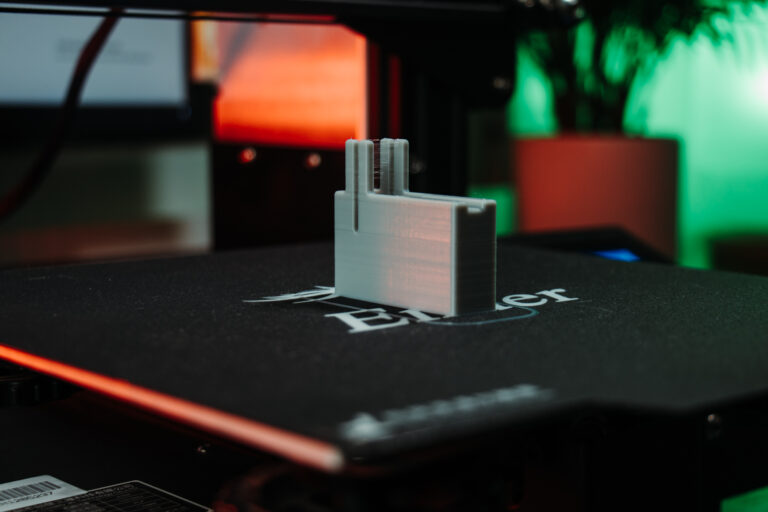

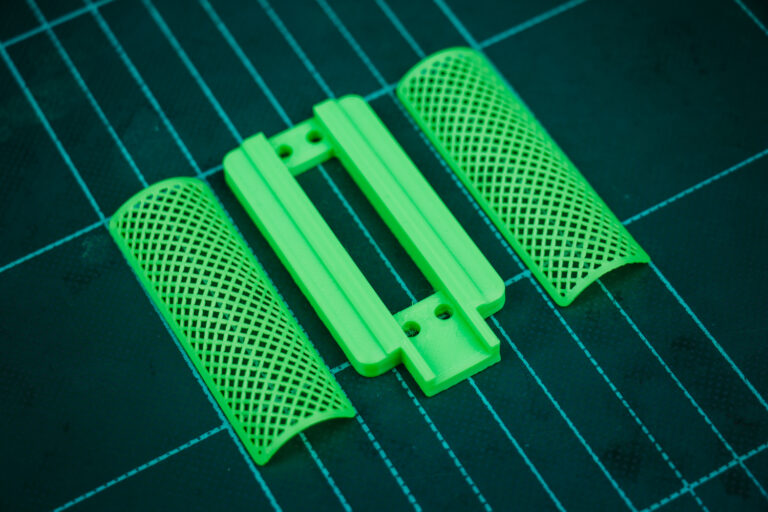

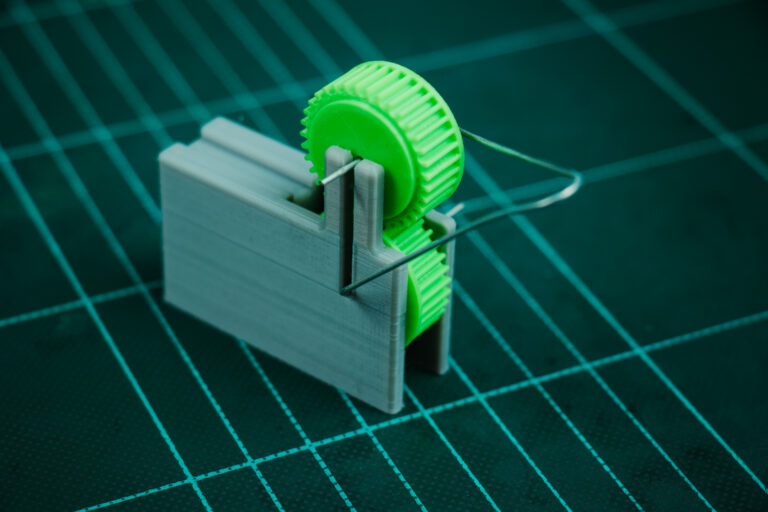

3D Printed DIY Ribbon Microphone

A ribbon microphone is one of the best home studio investments, when it comes to recording “harsh” sounding instruments.

Its unique frequency response and figure 8 polar pattern allow capturing the natural low-end of an electric guitar amp, violin, trumpet and many other high-pitched sound sources, as one could hear and feel them in their natural environment.

Dynamic, Condenser...why Ribbon?!

Whether it’s a DIY, Royer R121, Beyerdynamic M160 or any other microphone available on the market, mixing a ribbon with dynamic microphones, such as Shure SM57, Sennheiser MD421 or Sennheiser e906, provides the richest sound possible.

Blending these microphone types allows recording the most honest representation of the sound source frequency spectrum, which otherwise wouldn’t be possible with a single close miced SM57.

Imagine putting your ear on the amp speaker, do you expect SM57 alone to capture your amp full sound range this way?

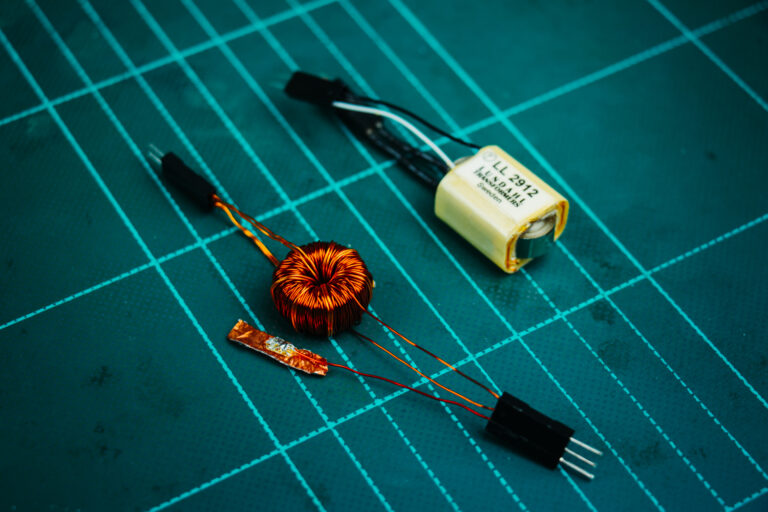

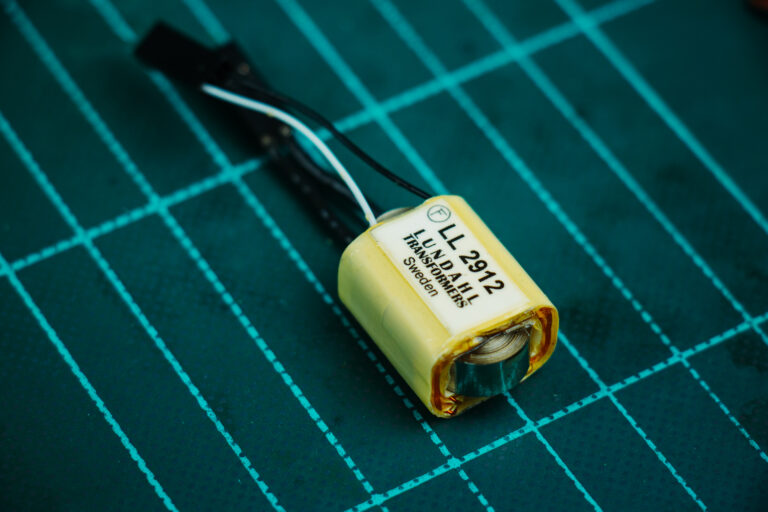

Premade vs DIY Transformer

The Lundahl and Messanovic transformers are the first obvious options for a premade transformer, but a DIY amorphous core transformer is very easy and cheap to make. It sounds at least as good as the premade ones while costing a fraction of them.

I always wondered whether a phone charger transformer can do the job, since it’s a step-down transformer 220V > 5V, which is a close enough ratio to the premade step-up 1:36 transformers.

Parts, Links and Recommendations

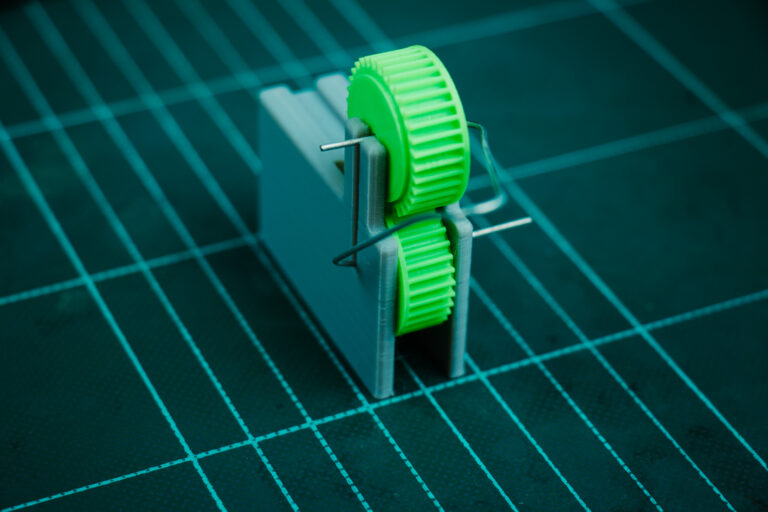

Transducer (Ribbon Motor):

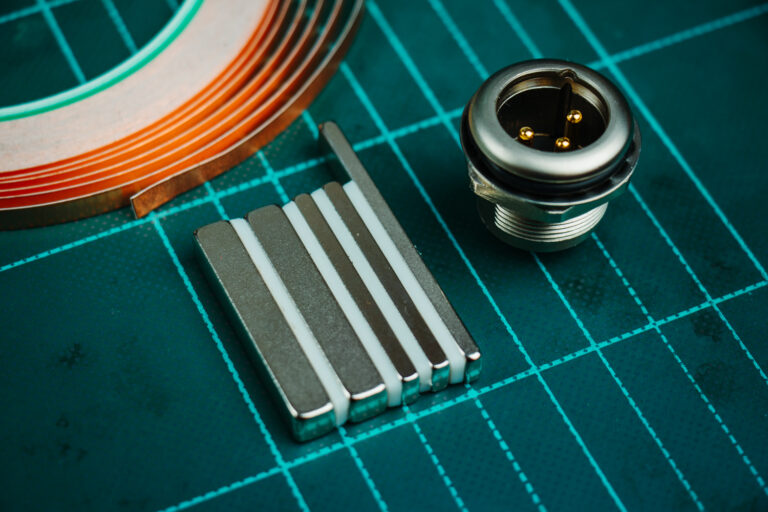

- Neodymium magnets:

– recommended: BX842 (1 1/2″ x 1/4″ x 1/8″ thick)

– thick: BX844 (1 1/2″ x 1/4″ x 1/4″ thick)

– long: BY042 (2″ x 1/4″ x 1/8″ thick) - Aluminum foil (2.5 micron)

- Copper tape (5mm)

Transformer:

- Premade Lundahl LL2912

- DIY Amorphous core toroids (10*14*4.5mm).

- Magnet wire (a.k.a coated copper motor wire) for DIY:

– primary winding: 28AWG / 0.33mm

– secondary winding: 26AWG / 0.4mm

XLR connector (socket) and alternatives:

Don't have a 3D printer?

There are many online 3D printing services, with many material and printing methods, such as FDM/SLA/SLS, but also many Facebook groups, through which you can locate your local 3D printing enthusiasts that can help you print the parts.

Obviously use Google maps to locate 3D printing services around you.

When using an online service, consider trying SLS printing, which should produce far more superior results than regular FDM printers, in a stuning matt grey color.

IMPORTANT:

Don’t forget to instruct them how to slice/print the mic and pop filter meshes, to reduce the chanses of failing prints. Even regular ink printing is a miracle when it works 😀